When first conceived, Sequential Injection had to be based on flow programming, since there is no other way how to meter and mix sample and reagent zones, when using only one valve and one pump. And the method did not really gain a wide acceptance in its original, macro, configuration. When the flow path was miniaturized using the lab-on-valve platform, the importance of careful flow programming, became obvious, as it allowed the SI based assays to be optimized for an intended task – high throughput or high sensitivity – as documented in this section.

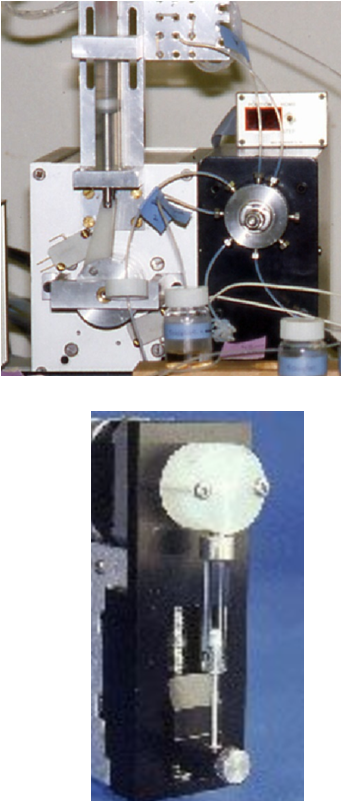

In all fairness, we must acknowledge that all these advances became feasible only, when a suitable technology became available. The case in point is the device that is the heart of the system - the pump. What was available at the outset was a home made device, fabricated from a peristaltic pump – a cam driven syringe pump that generated a sinusoidal flow rate. (Ruzicka and Marshall 1990). While syringe pumps were available at that time, none of existing models could aspirate small discrete volumes at a controlled flow rate. Availability of Cavro pumps allowed development micro SI- LOV technique, which, being now a mature technology, becomes somehow limited by the performance of this pump. The advantages of Miligat, continuous refilling, and wide dynamic range, are result of ingenious design and meticulous development focused at the needs of SI technique, now almost perfectly fulfills the needs of LOV platform.

However, both Cavro and Miligat have their shortcomings, as mentioned in the Outlook (2.6.1.). Hopefully all possibilities are not yet exhausted , and there is a simple solution to design of an “ideal” drive for flow based assays

J. Ruzicka & G.D. Marshall, Anal. Chim. Acta, 237, 329, (1990).

SUMMARY

2.2.20.

Once you have exhausted all possibilities, and

failed there will be one solution, simple and

obvious, highly visible to everyone else.

SNAFU